Machinery and Equipment

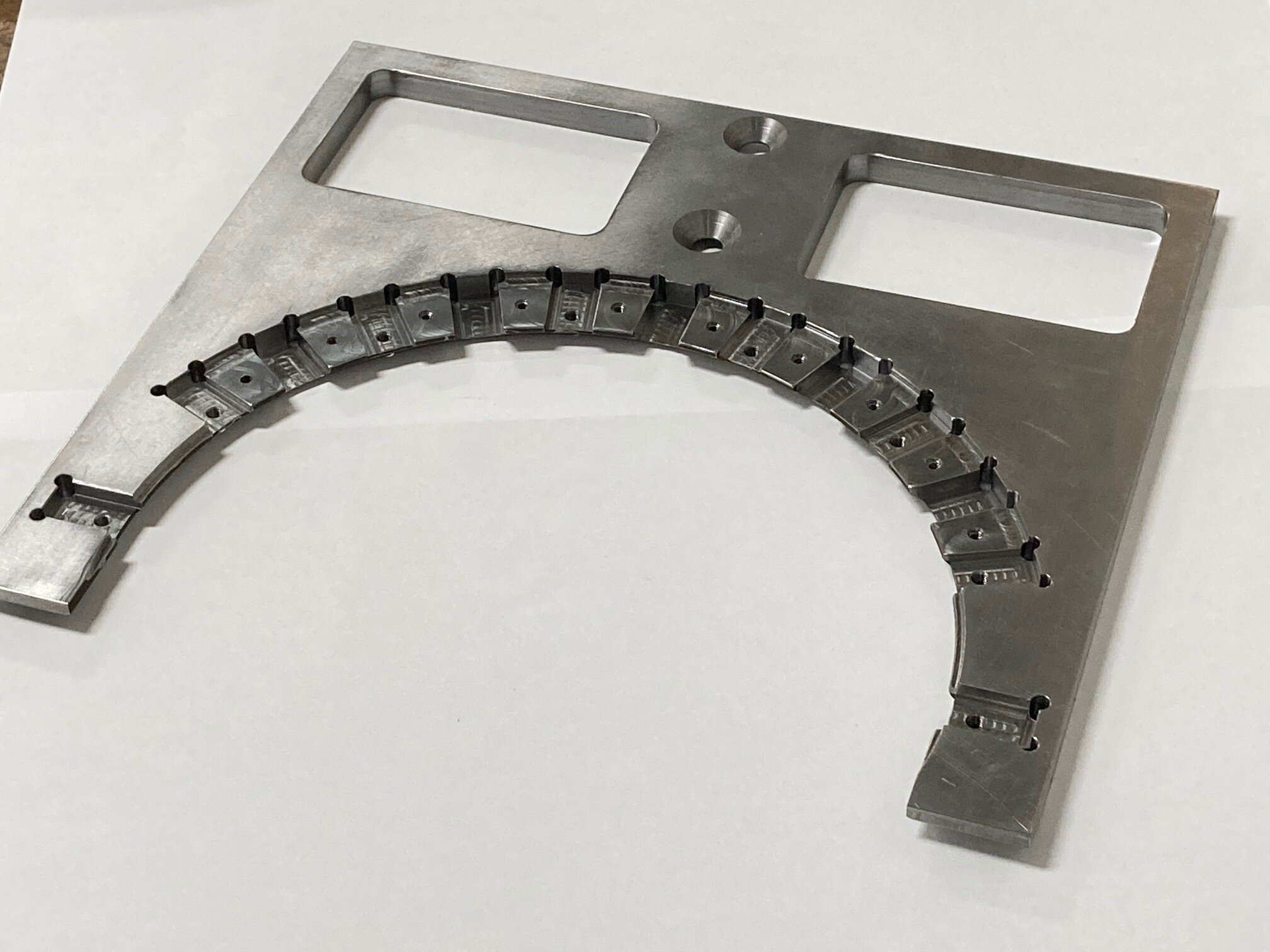

Wire EDM’s

By using a thin strand of wire as the cutting tool, it creates a linear line which is commonly used to cut all the way through the material. Wire EDM is best suited for projects that have intricate tolerances, material stress limitations, and/or surface finish requirements.

In the Wire EDM cutting process, tolerance and surface finish are related, as both are controlled by the number of passes the machine takes. The more passes, the higher the precision AND the better the finish.

CNC Hole Popping

3 Axis travel

High-quality surface finish capability

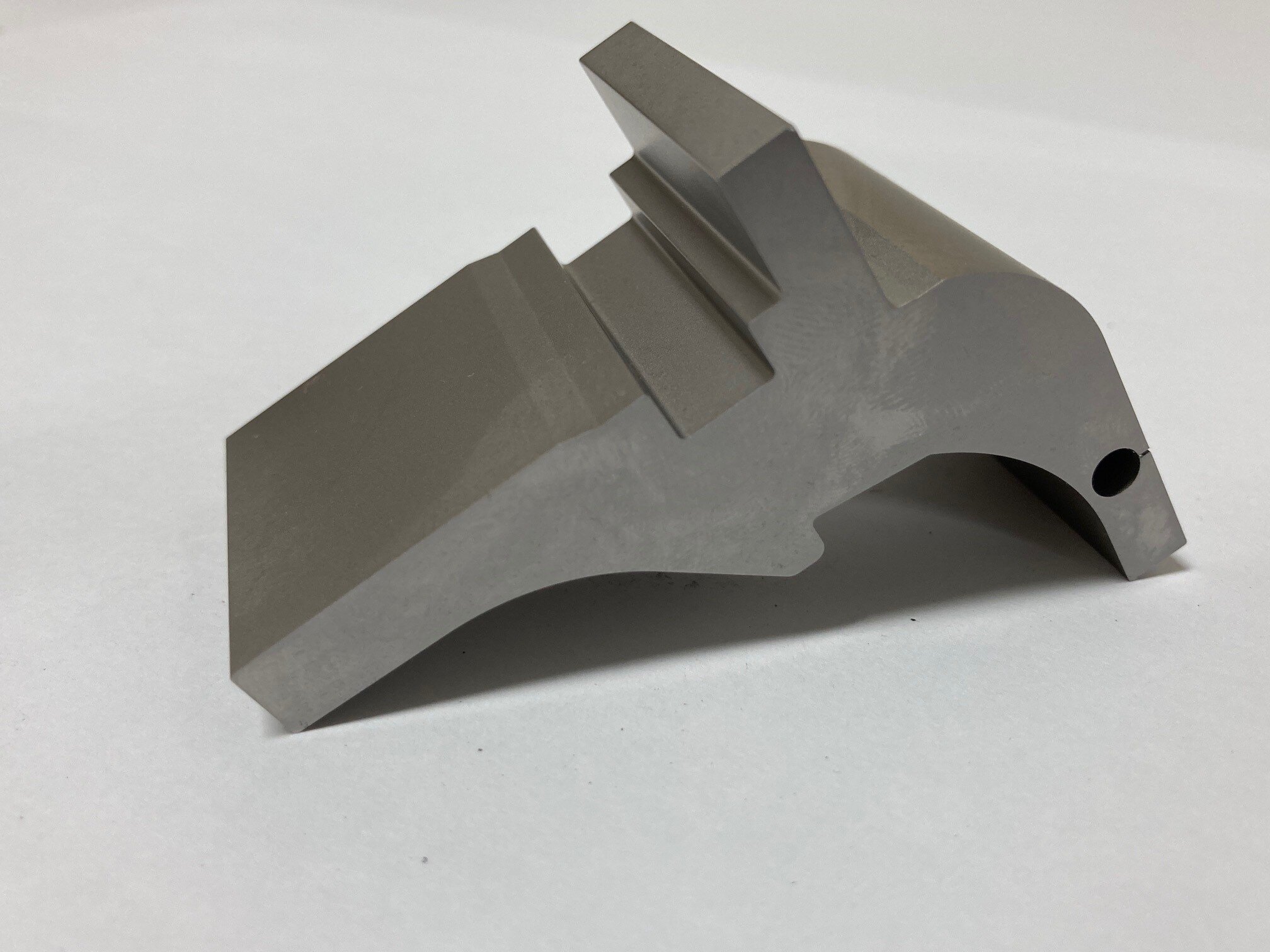

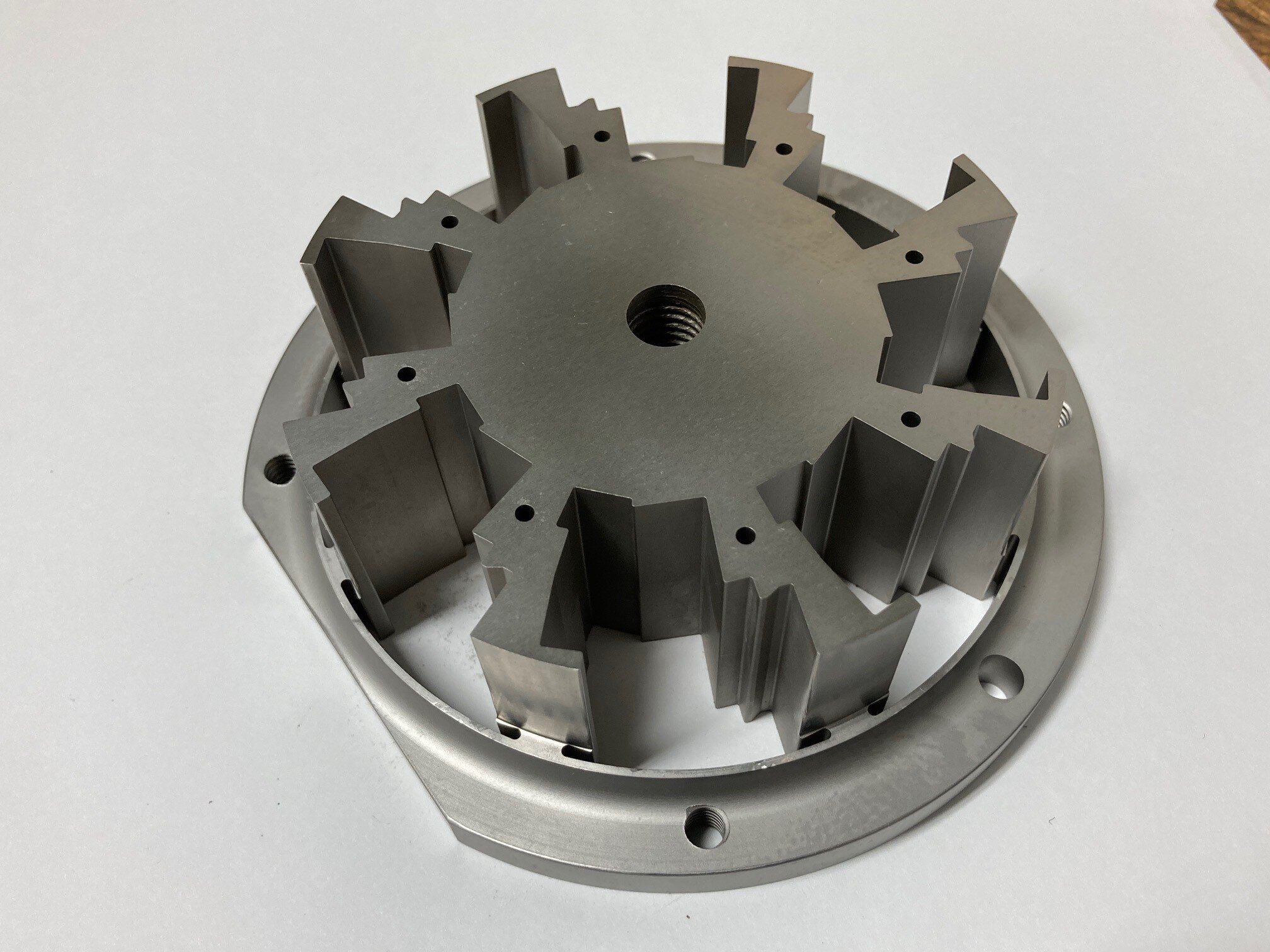

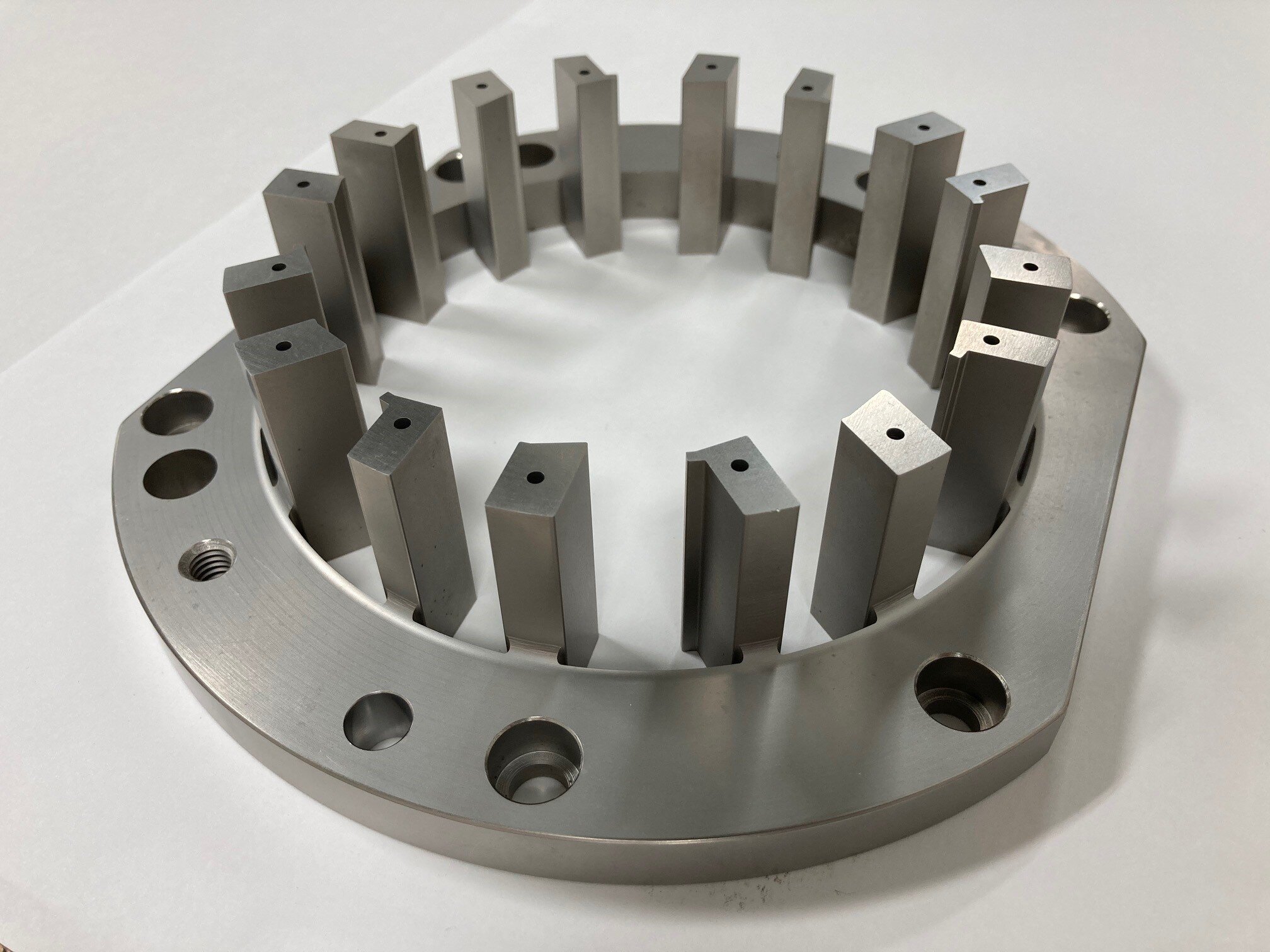

CNC Machining Services

Computer numeric controlled (CNC) machining is synonymous with modern manufacturing practices. Precision CNC machining services greatly increase reliability and repeatability, while reducing the potential for human error. Most modern manufacturing centers are controlled via computers, including EDM and waterjet machines. However, CNC machining usually refers to conventional manufacturing techniques, such as CNC milling, CNC turning, and CNC surface grinding.

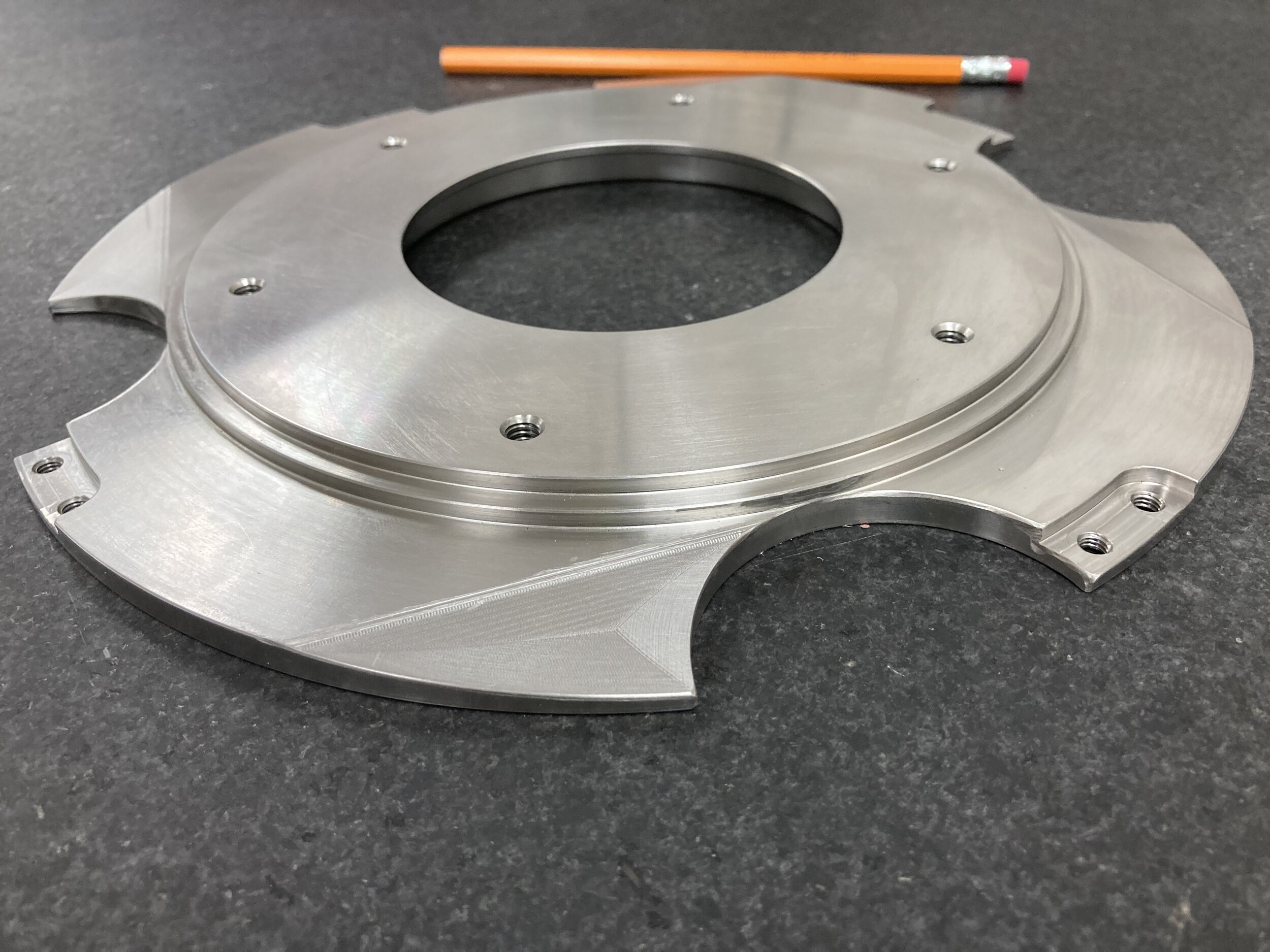

CNC Milling Services

Computer-controlled, rotating cutting tool produces a shape or form with great reliability and repeatability.

+/- 0.0005” typical tolerances

All metals, alloys, & plastics

True 5-axis machining

Hard milling and machining services

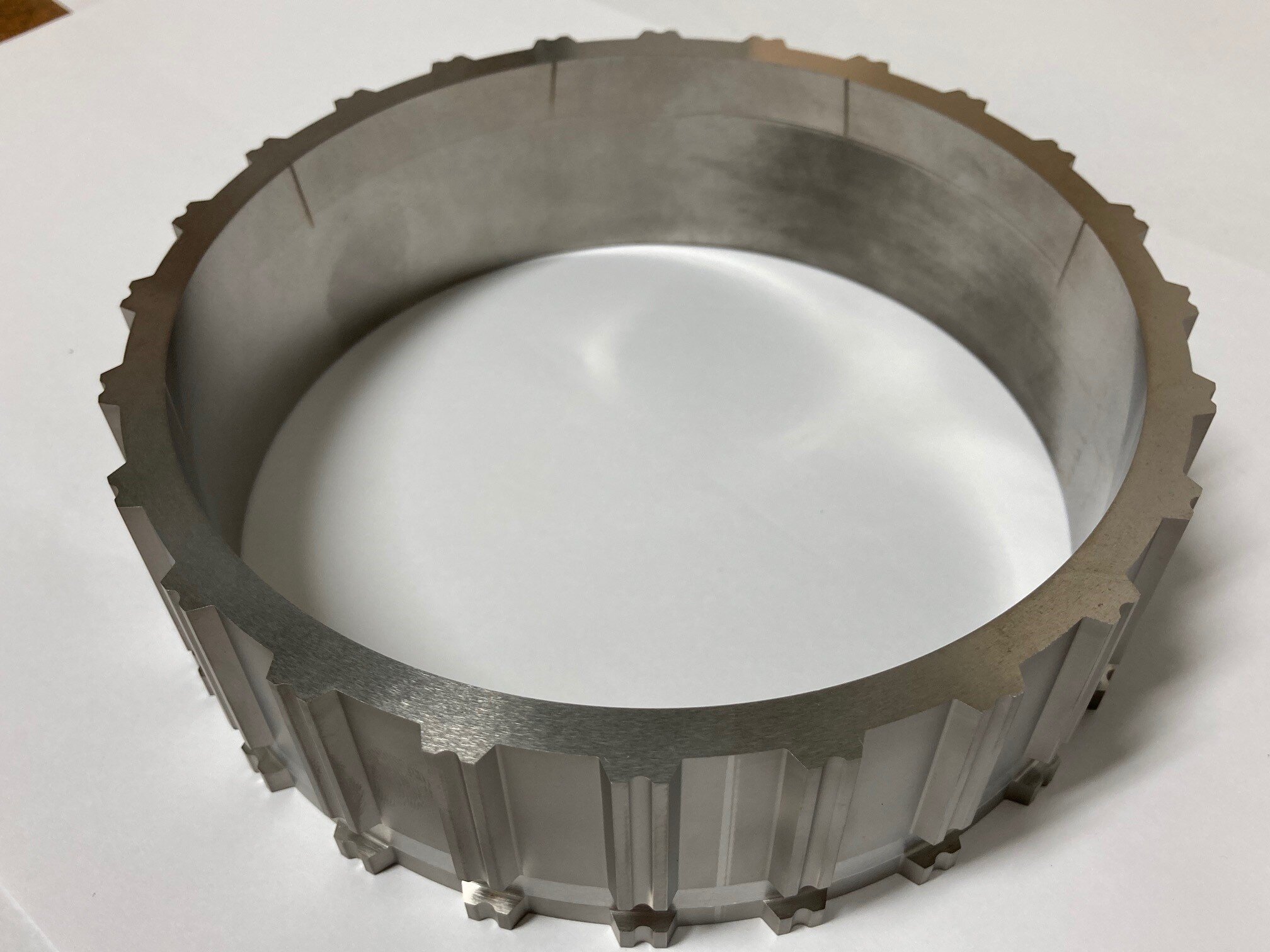

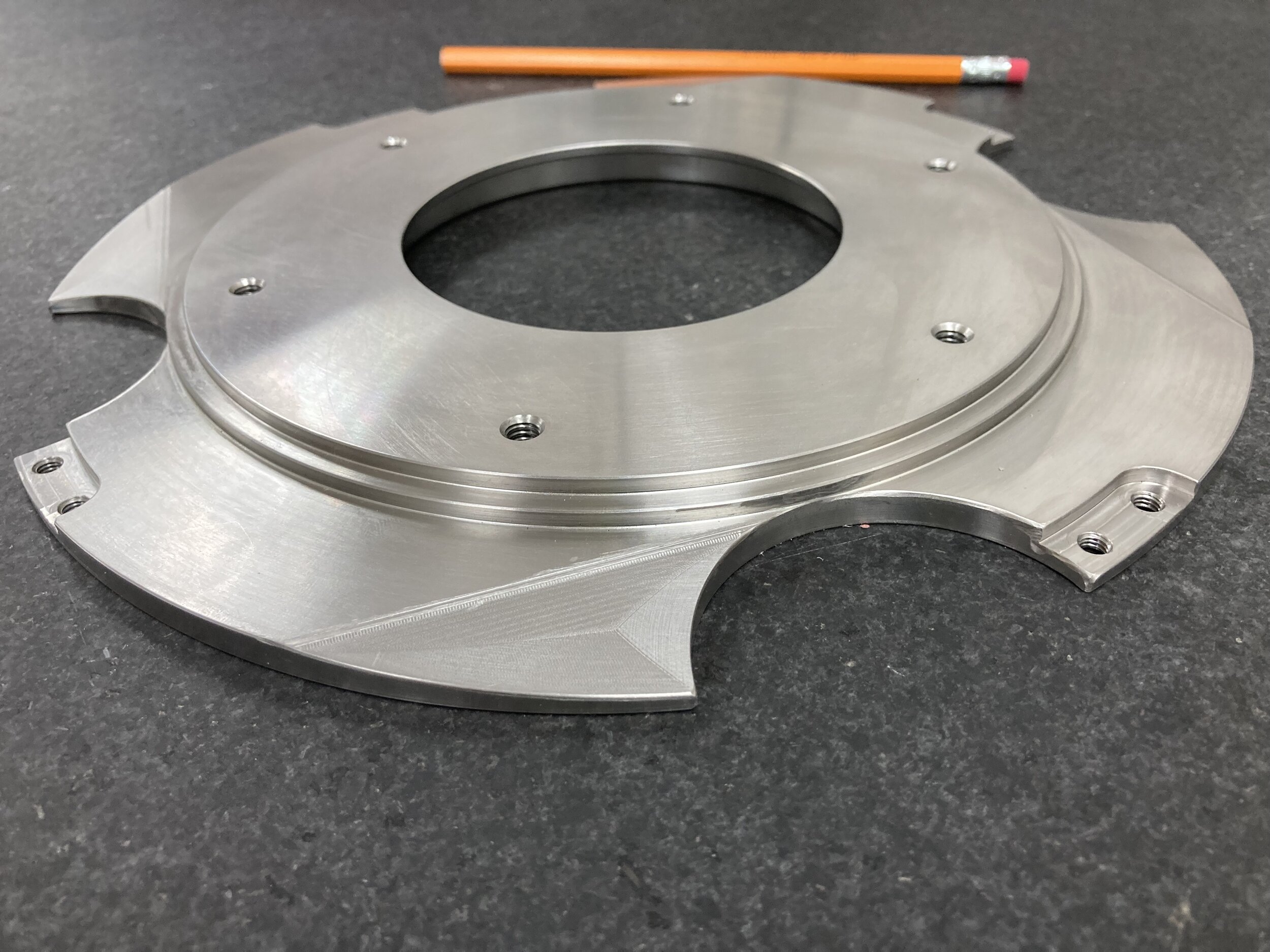

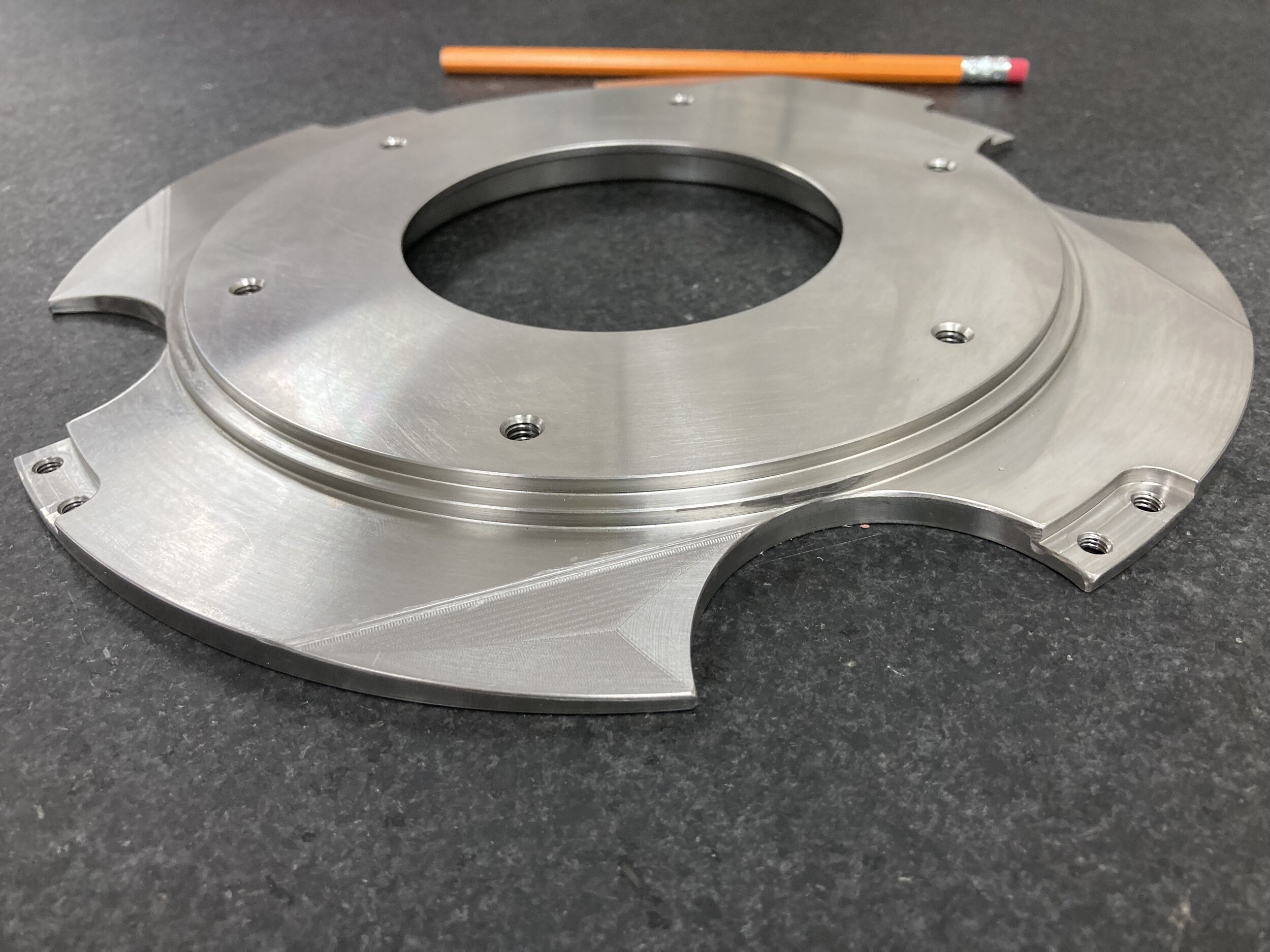

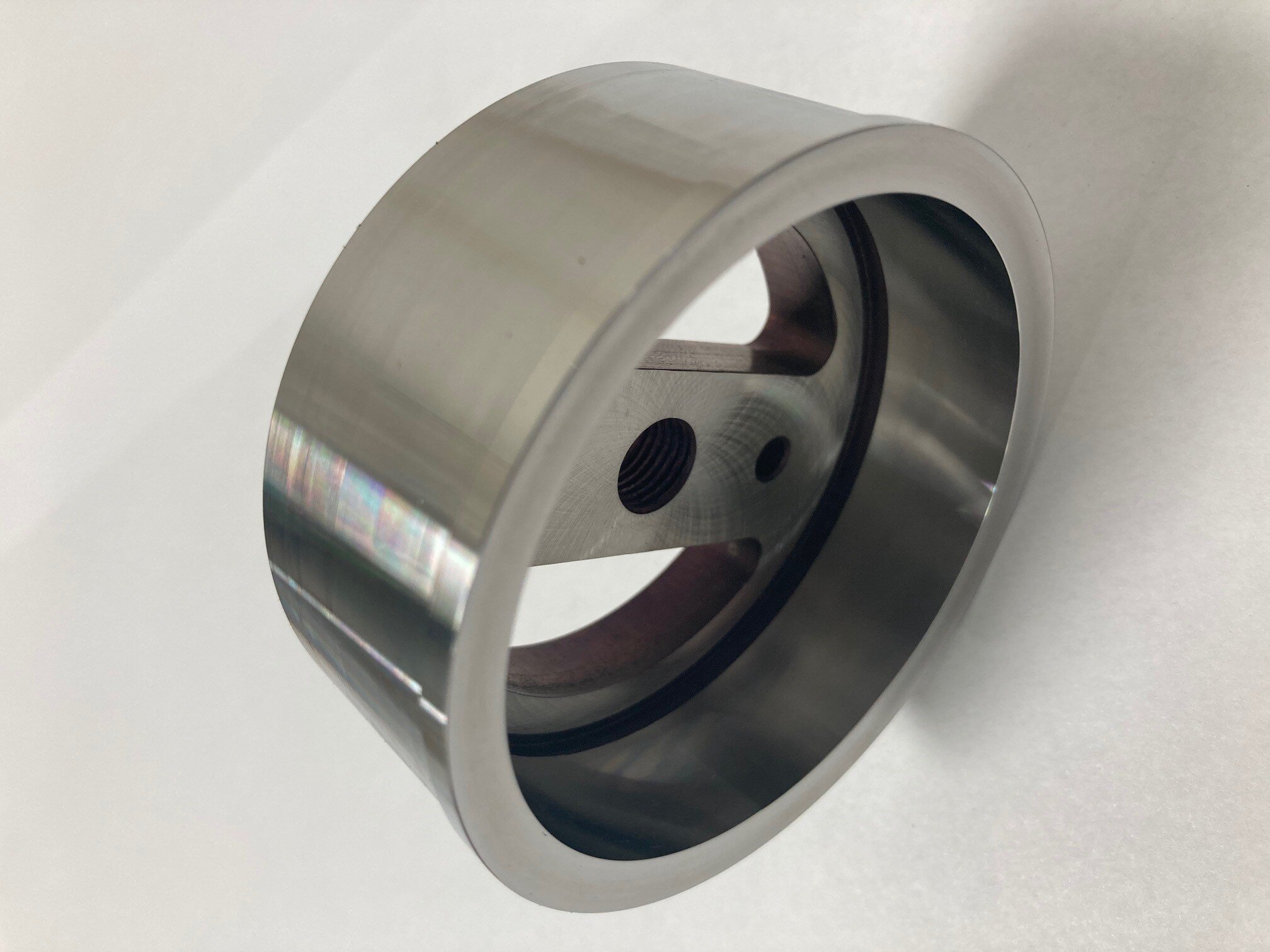

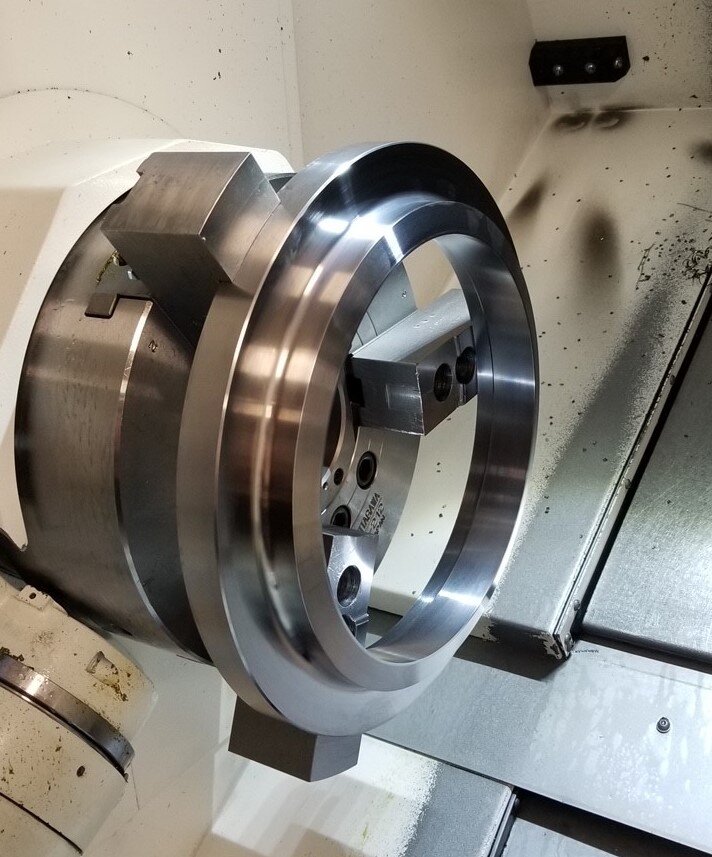

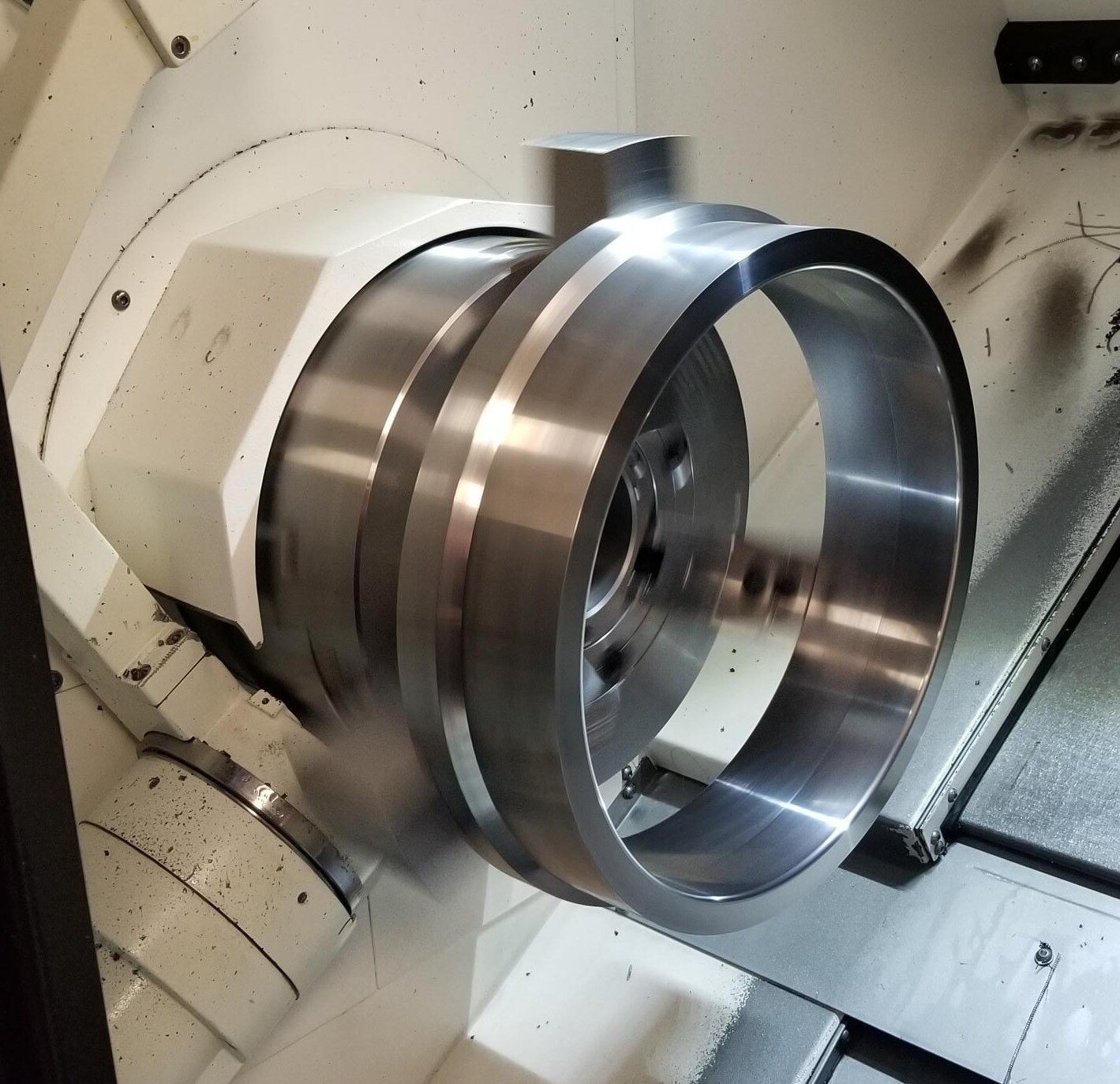

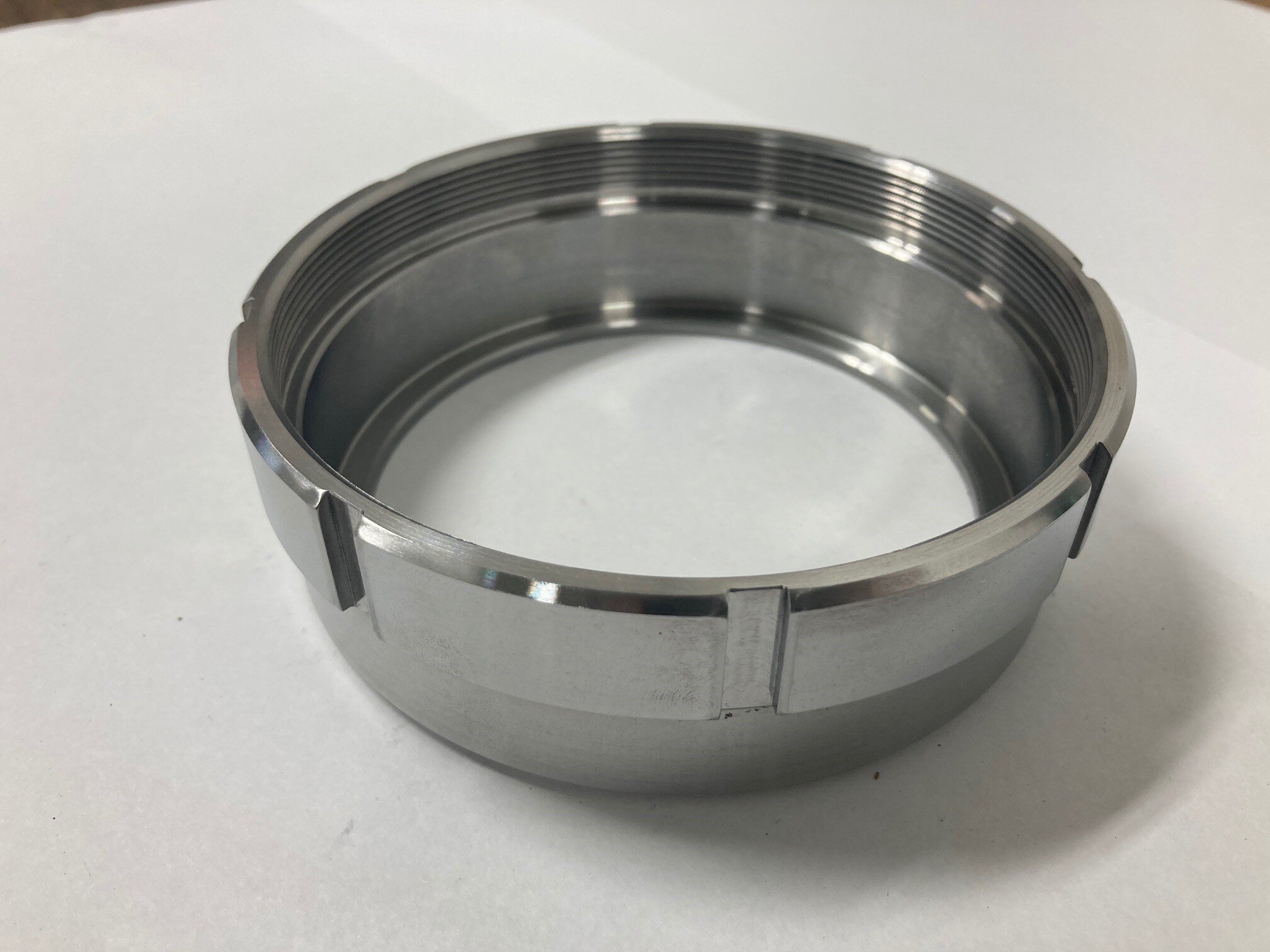

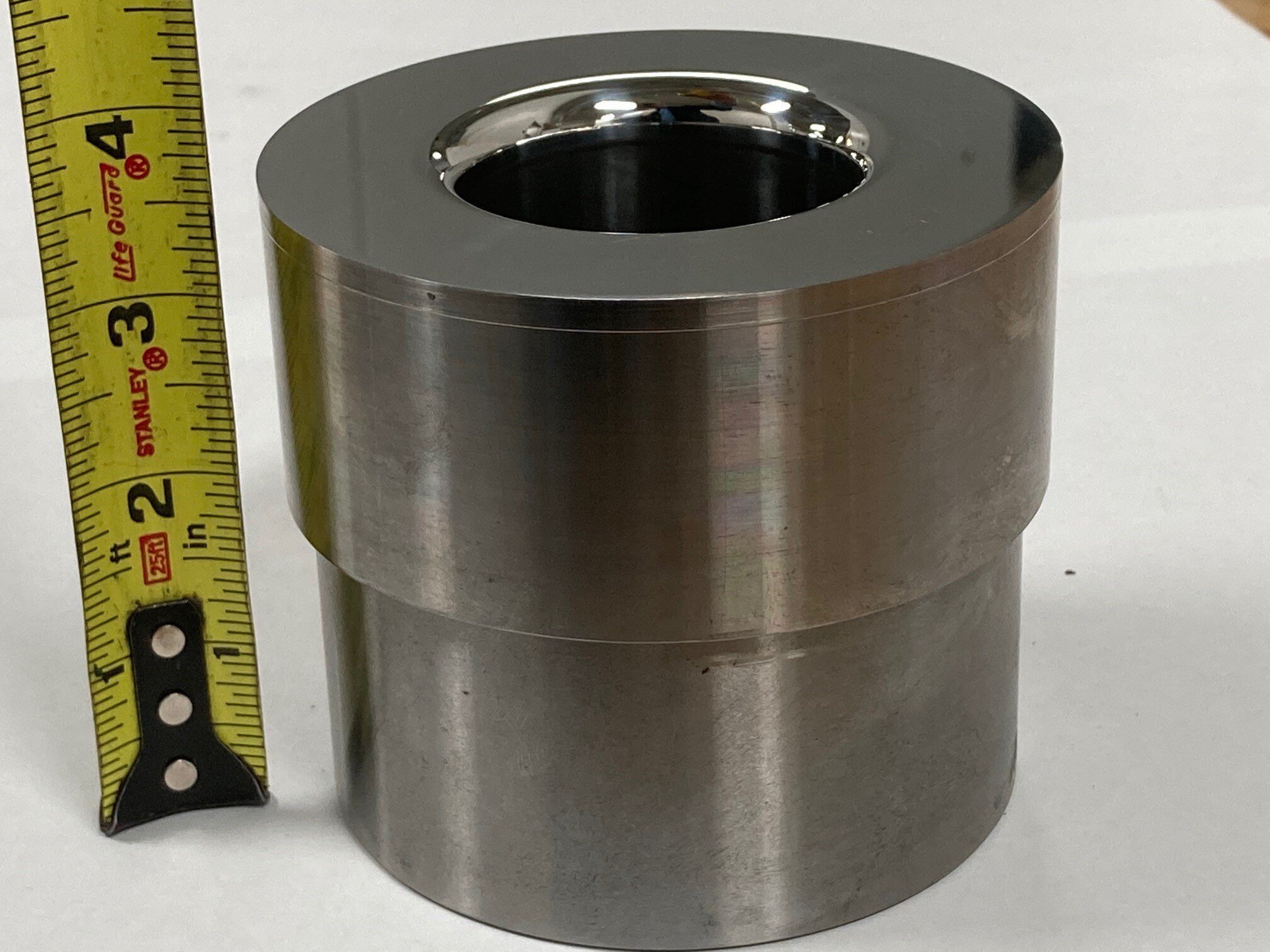

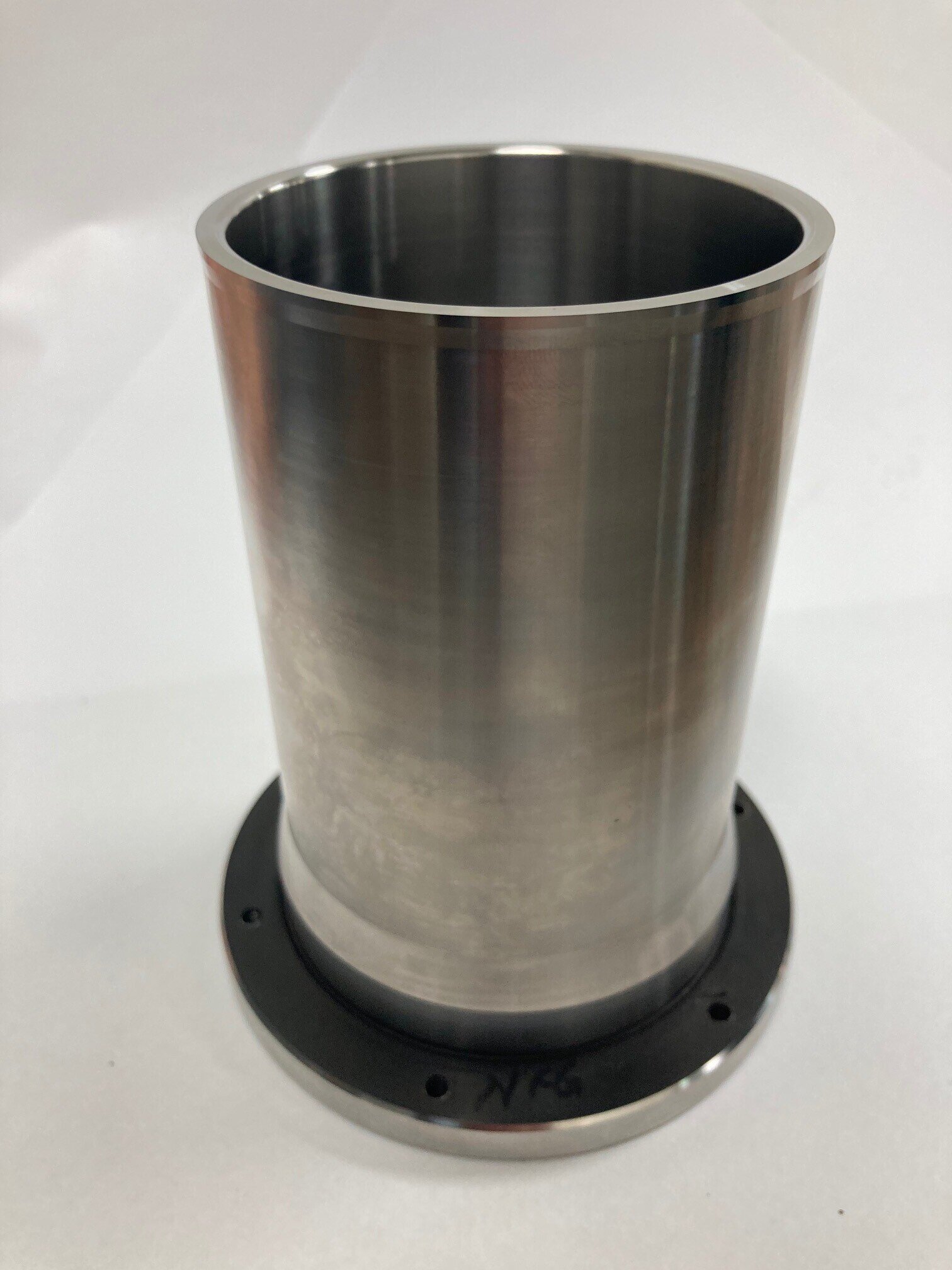

CNC Turning Services

High level of concentricity with a ✔16 or better finish.

.0002” to .0005” of tolerance

Hard turning services

All metals and alloys

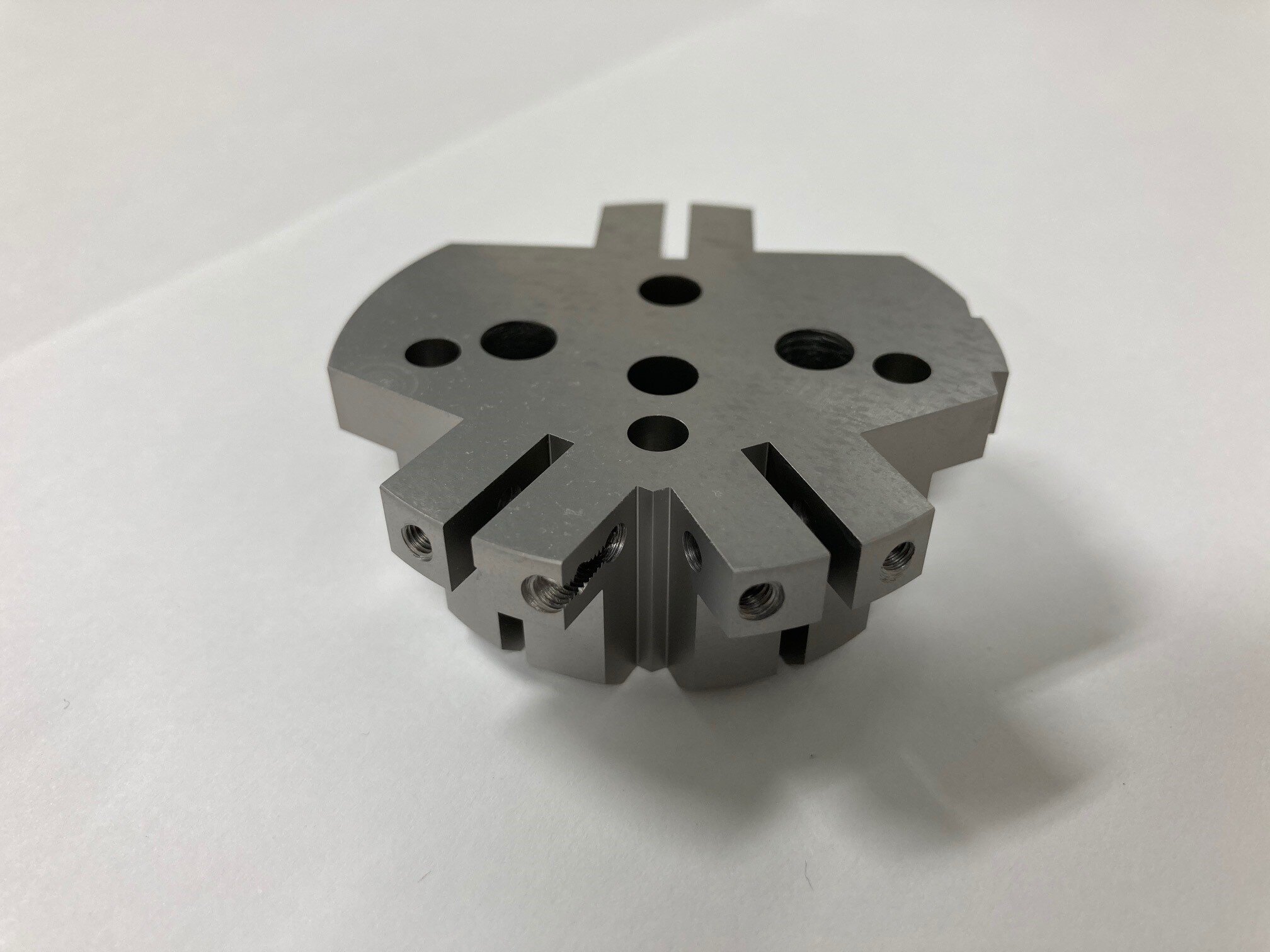

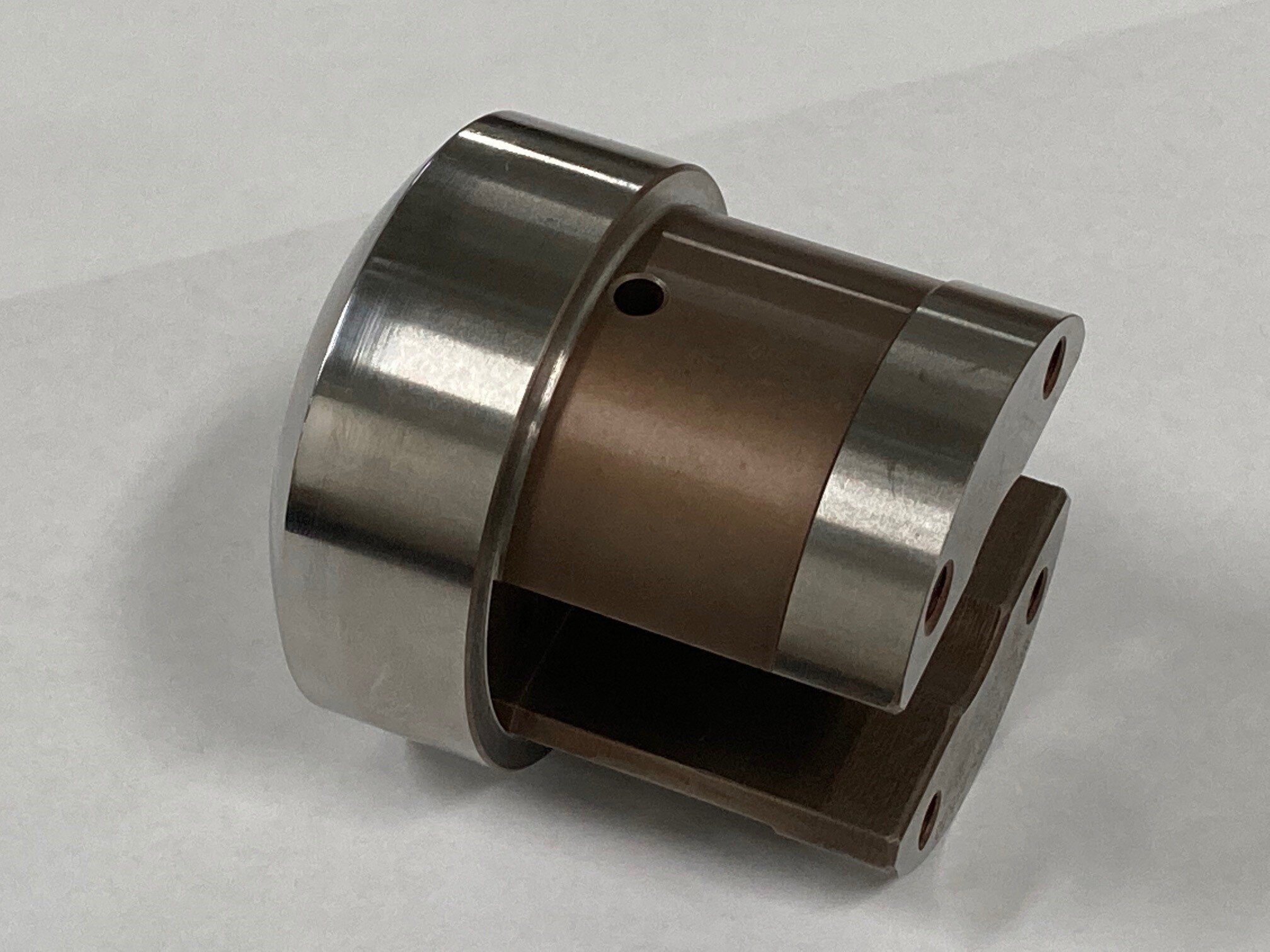

ID/OD Grinding Services

Our Precision I.D. Grinding Department is capable of grinding parts from .250” to 12” inside or outside diameters by 8 inches deep. Our Precision Internal Grinding Department can also grind faces, tapers, and radii.

Conform’s expert precision OD grinding staff grind and finish to tolerances up to +/–0.0001, line to line fit with concentric tooling to a 16 or better finish

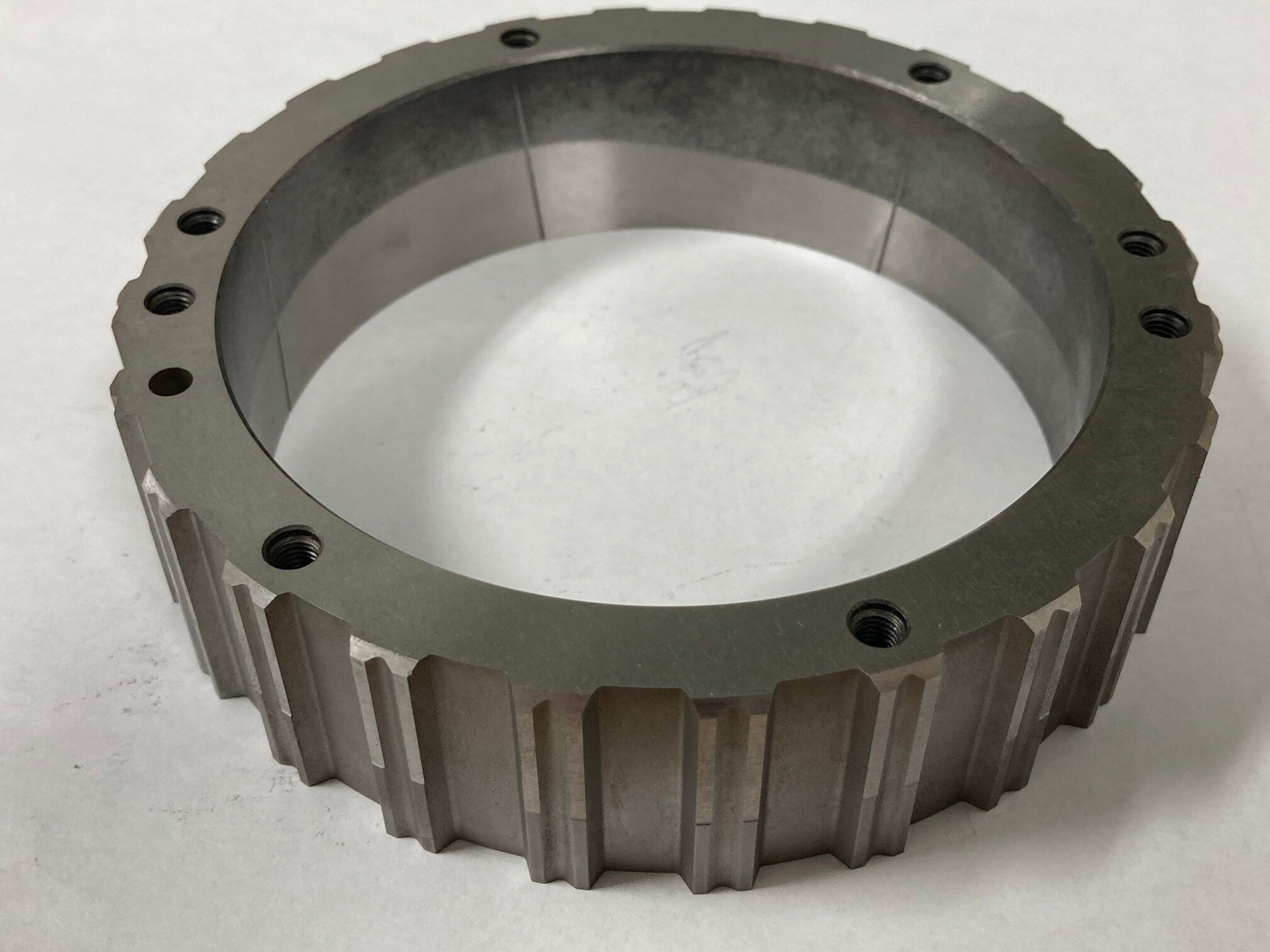

Surface Grinding Services

High-speed abrasive wheel removes small amounts of material to produce tight tolerances.

+/- 0.0001” typical tolerances

All metals & alloys

Flatness/parallelism/squareness